Precision Machining

Specialties & Industries

Quality Assurance

On The Mean is a CNC Machine Shop with Precision Machining Capabilities

On The Mean is a CNC Machine Shop that puts precision, efficiency, and quality at the forefront of every machining contract we take on. We have state-of-the-art equipment that is used to both machine precision parts and test them to ensure our quality guarantees are met. As a Veteran Owned Business, we know the importance of honoring the contracts we accept and completing each job reliably. We also know how important it is to offer solutions that add to the value of selecting us to complete precision machining jobs. Therefore, we offer value-added services including no markups on materials used to machine your parts and discounted shipping. Our machining process allows us to be lean enough to pass on savings to our customers who can be local or in the country’s most distant areas.

Trusted by Industry Leaders

Precision Machining

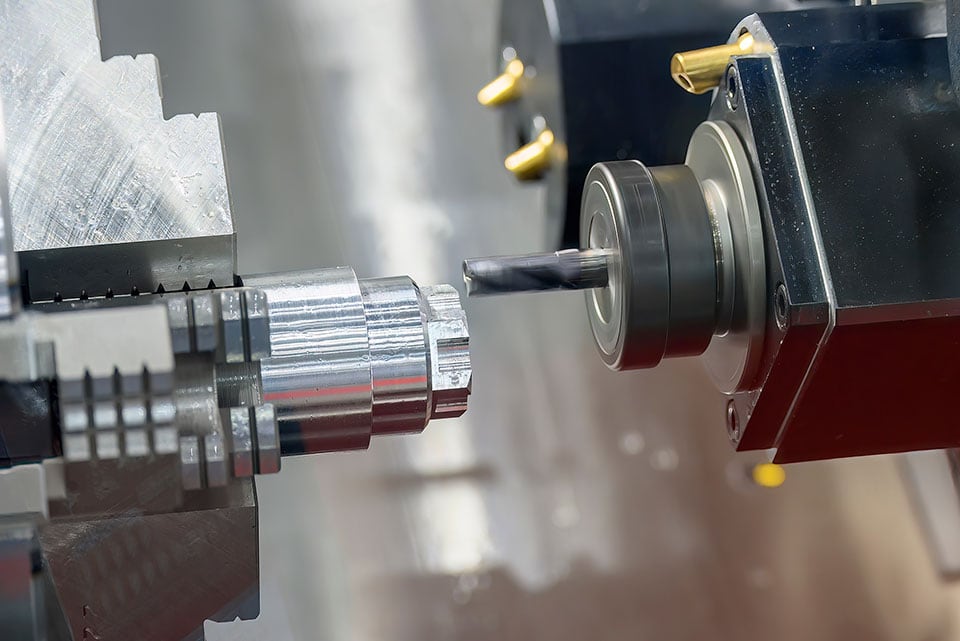

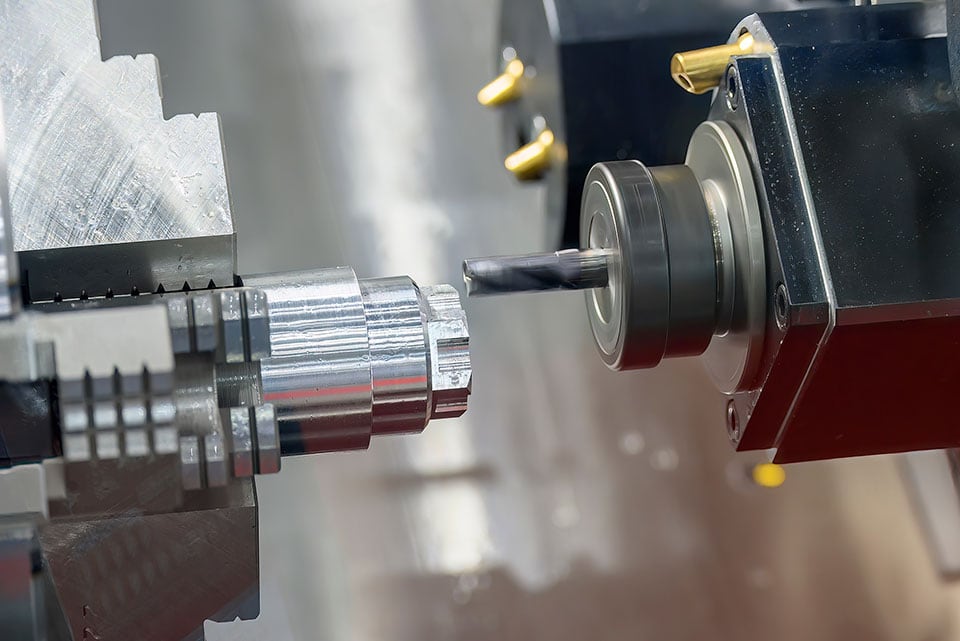

The ability of On the Mean to complete precision machining jobs with exceptional efficiency is made possible thanks to our MAZAK Multiplex 6200Y machining center. This CNC machining center features two turrets that allow for 4-axis machining on both sides of a part. This programmable equipment allows us to complete many machining jobs in half the time it would take a traditional 4-axis single turret machine to do the same work. This efficiency allows us to complete precision machining work rapidly without having to sacrifice quality. Our website includes a wealth of information about this 4-axis MAZAK machining center, including its specifications and the part dimensions it is well suited to working within. We invite you to learn more about our advanced equipment and then contact us to obtain a competitive quote on your next precision machining job.

Specialties & Industries

The equipment and experience we have makes On the Mean a reliable Machine Shop for a diverse range of precision projects. From machining intricate custom bolts with one off thread pitches for the transportation industry to handling surplus machining work for other Machine Shops in need of support, we work with a wide variety of customers. Our machining processes include drilling, boring, turning, grooving, milling, threading, tapping. We can handle significant volume thanks to our dual-turret 4-axis machining center featuring a bar feeder and a parts unloader for nonstop production. Some of our specialties include machining hydraulic fittings and a wide range of gears.

The precision of our 4-axis, two-turret MAZAK Multiplex 6200Y machining center allows us to machine a limitless variety of parts. If your part or parts require 4-axes of machining capacity and range in size from roughly 2” to 6” in diameter and up to 4” in length, On the Mean is the OH Machine Shop to contact. You can read more information on our informative website to develop a better understanding of our skillset, machining capacity, and target industries. After you do so, we invite you to request a CNC machining quote from our team.

Quality Assurance

Quality means everything to our team at On the Mean. From the precision of our programmable machining center to the testing equipment tools we utilize; the quality of your machined parts is never compromised when you contract us. We have invested heavily in equipment from top brands like TESA Technology that is involved in the testing of each machining run we complete.

Having state-of-the-art testing equipment in-house allows us to ensure quality is met throughout every step of the precision machining process. This means that prior to shipping your machined parts or dropping them off to you directly, each piece will have undergone a thorough quality review. If you want to confirm that our quality assurance program meets your standards, you can review more details about the processes we follow and our tools.

Recent News

Contact us today for a free estimate.

"*" indicates required fields