A Low-Cost OH Machine Shop with Dual Turret 4-Axis CNC Machining Capabilities

When we formed On the Mean, our primary goal was to become a lean machine shop that generated cost savings due to machining efficiency. Our goal in doing so was to be able to pass both cost savings and time savings onto our customers. We knew that state-of-the-art CNC equipment would be needed to accomplish this. This is why one of the first investments our shop made was in the MAZAK Multiplex 6200Y machining center we use to complete each job.

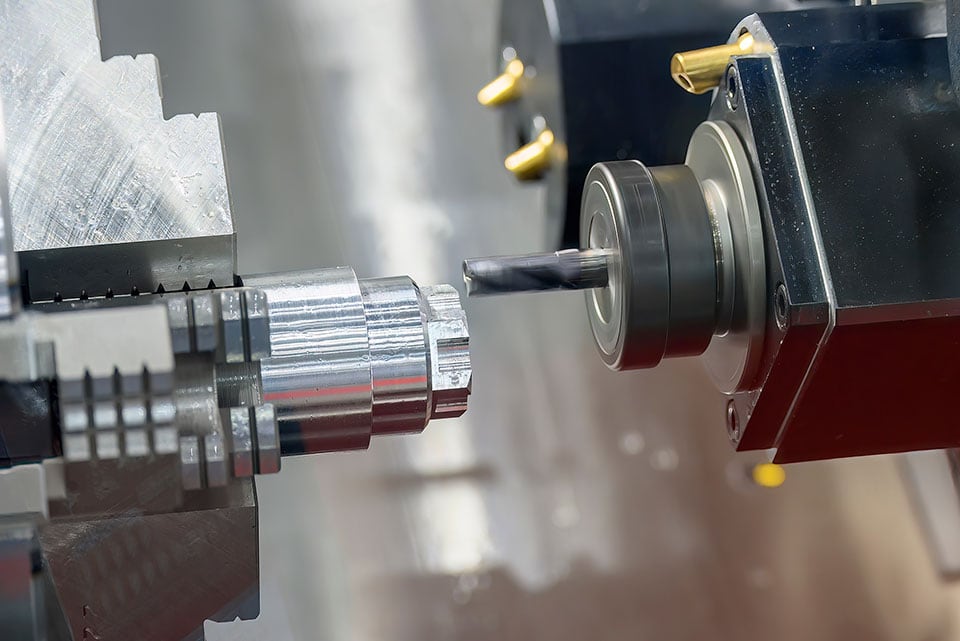

Thanks to MAZAK’s innovative design, this machining center is easy to program, reliable in its precision, and efficient. These qualities provide us with the ability to machine tight-tolerance parts in short fashion. Plus, its live tooling design provides us with a single machine that has the capabilities of a CNC mill and lathe wrapped in one. The benefits of our machining center’s live tooling capabilities are enhanced further by its dual-turret design. This design means that we can machine both sides of the part simultaneously. This allows us to produce parts that require 4-axes of machining in half the time it would take standard equipment.

Two Turrets and 4-Axes Allow Us to Rapidly Machine Precision Parts

On The Mean is an ideal shop to contract for precision machining jobs in OH, PA, and MI that require 4-axes of machining capacity. However, our MAZAK Multiplex 6200Y machining center provides us with benefits that go far beyond a traditional 4-axis CNC machine. This is thanks to its dual turret design. With two turrets that are each designed with 4-axes of machining capacity, we can often utilize it to cut machining time in half for tight tolerance parts. That allows us to complete jobs in a brief turnaround time and share the cost savings wrought from our efficient machining methods with customers.

On The Mean specializes in producing smaller parts that must be machined within tight tolerances in order to work as needed in their intended application. Though these parts are on the smaller side, our MAZAK Multiplex 6200Y center can work with a wide scope of part sizes. However, its sweet spot includes parts that are roughly 2” in diameter and less and up to 4” long. Despite this being our sweet spot, when needed we can safely machine parts with diameters up to 6”.

Given the breadth of components that fall within this size range, our capabilities are effectively limitless. Plus, the efficiency of this machining center provides us with flexibility in the volume of parts you can contract On the Mean to produce. We are sought out to machine single components as well as for higher volume jobs reaching into the tens of thousands of parts per year. You can reach out to us today to discuss your needs and find out quickly if we are the ideal shop to work with on your next tight tolerance machining job in OH, PA, or MI.

A Woman Owned OH CNC Machine Shop with State-of-the-Art MAZAK Equipment

Our MAZAK Multiplex 6200Y machining center is designed to work with an extensive variety of popular machining materials. Our equipment can machine materials such as carbon, stainless, and pre-hard steel, stock aluminum, copper, brass, and even plastics. However, it is not just our machining center that allows us to work with these materials. At our Woman Owned Business, the production of your parts will be handled by an NTMA certified machinist. Our machining expert has a wealth of experience working with these diverse materials and doing so for a variety of industries. You will benefit from this combination of experience and advanced machining equipment when you contract On the Mean for your competitively priced machining job.

Can't Find What You're Looking For?

Try Searching for a Keyword Below

Recent News

Contact us today for a free estimate.

"*" indicates required fields